I am a geek. I have years worth of CDs and DVDs saved up that I burned myself or that I received in paper envelopes with computer hardware. Yes, much of the software is Linux distros. All in all, the stack of media with no cases has grown unwieldy, and though the containers that blanks come in work OK, I wanted something a bit more flashy.

And, oh by the way, I do have a lot of CDs and DVDs in my den that do have cases.

So I bought this media cabinet for a couple of dollars at a yard sale:

My idea is to add spindles to hang lots of stored CDs and DVDs on. This isn't good for stuff you use often, but that isn't what I want to store.

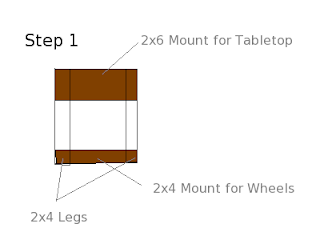

Step 1 is to cut some crossbeams to fit into the media center. I used 1x3 lumber. I cut it so it fit snugly into the cabinet. Test fitting it is always a good idea.

Step 2. I placed 2 CDs side by side on the board along the center line along the board and marked the center with a pencil.

Step 3. I drilled out 1/2 inch holes not quite all the way through and put in 1/2 inch dowel rods at a length chosen to not stick out from the media cabinet. Again I test fitted to make sure the piece fit properly. The dowels are glued in with Elmers wood glue.

Step 4. For my heft collection of CDs I wanted a lot of spindles, so I copied the design three more times. All copies were also test fitted. Oh, and everything was sanded, of course.

Step 5. I spray painted all of the holders, once assembled, gloss black so they would blend in with the media cabinet.

Step 6. After the holders were dry, I removed some of the shelves from the media cabinet and inserted the holders where I wanted them, using CDs to verify the spacing. I placed I single screw into each holder through the media center back. This was more than enough to hold them since they fit snug.